Information about grain drying

Smoke outlet

Can be ordered on the right or left side, on the top or on the backside.

Cover plates

The heater for grain drying are covered with electroplated steel plates on the outside. Insulation: Cover plates are insulated with 30 mm mineral wool on the inside.

Corner posts

Heaters from type V-550 are delivered with air cooled corner posts.

Burner

The heaters are delivered for oil or gas. The burner must be in high/low or modulating execution.

Fan section

Is delivered separately for mounting underneath the heat exchanger section. Can be delivered in a closed execution for canal connection or with inlet nets.

Fans

Are mounted according to each system, so that capacity and pressure always are most optimal for the drying process.

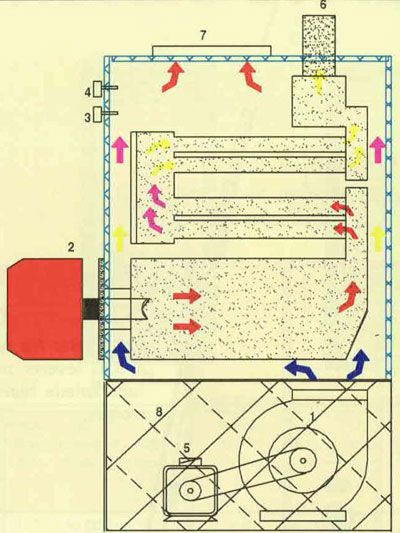

Air temperature max 80o C type V

The flame from the oil/gas burner heats up the combustion chamber and the following convection pipes. The process air, which needs to be heated, is supplied by the heaters fan. The air is passing by the heat exchanger and gradually absorbs the heat energy from here, so that the process air temperature rises, while the smoke gasses are cooled down. The heat exchanger’s construction makes sure, that the energy from the burner is used at the best, which gives a very high efficiency.

- Fan

- Oil/gas burner

- Combi thermostat

- Overheating thermostat

- Motor

- Smoke outlet

- Process air out

- Fresh air inlet

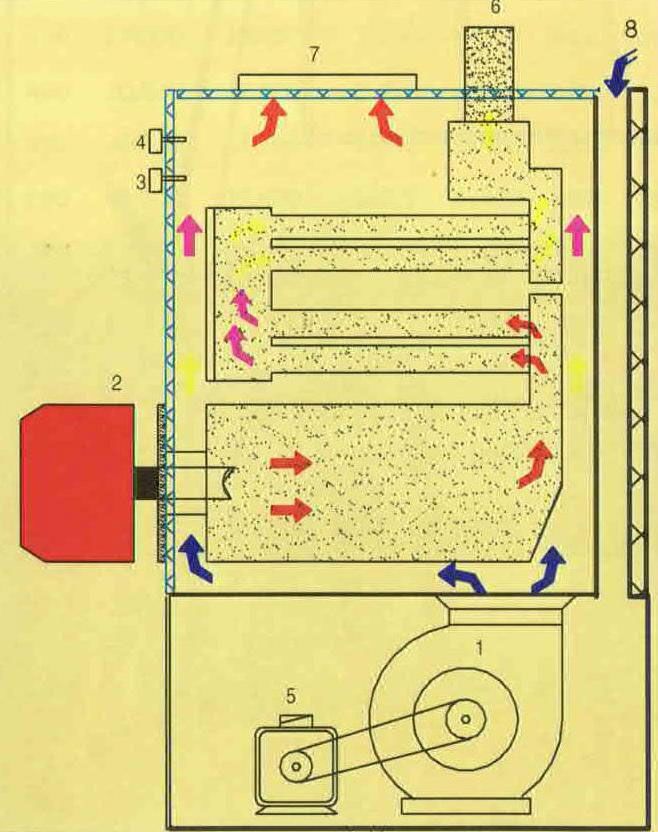

Air temperature max 130oC type HT

The heater is made with double cover. The process air is sucked in along the heaters side- and back plate. Hereby the air is preheated, before it reaches the fan and the final heating is completed over the heat exchanger, as in a standard heater. By this execution you can obtain a process air temperature up to 150o C. By preheating the air, the heater keeps the high efficiency even by high air temperatures.

- Fan

- Oil/gas burner

- Combi thermostat

- Overheating thermostat

- Motor

- Smoke outlet

- Process air out

- Fresh air inlet

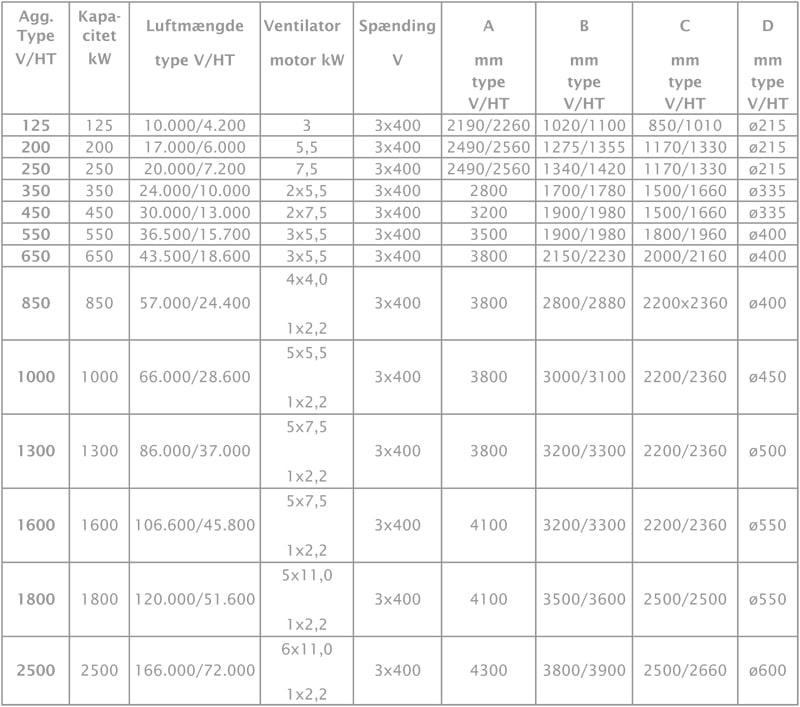

Technical information

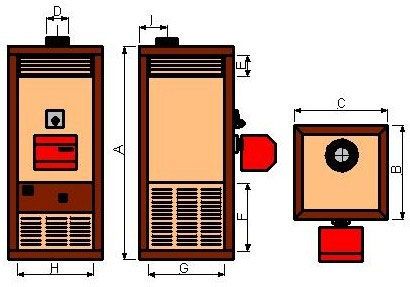

Product sketch

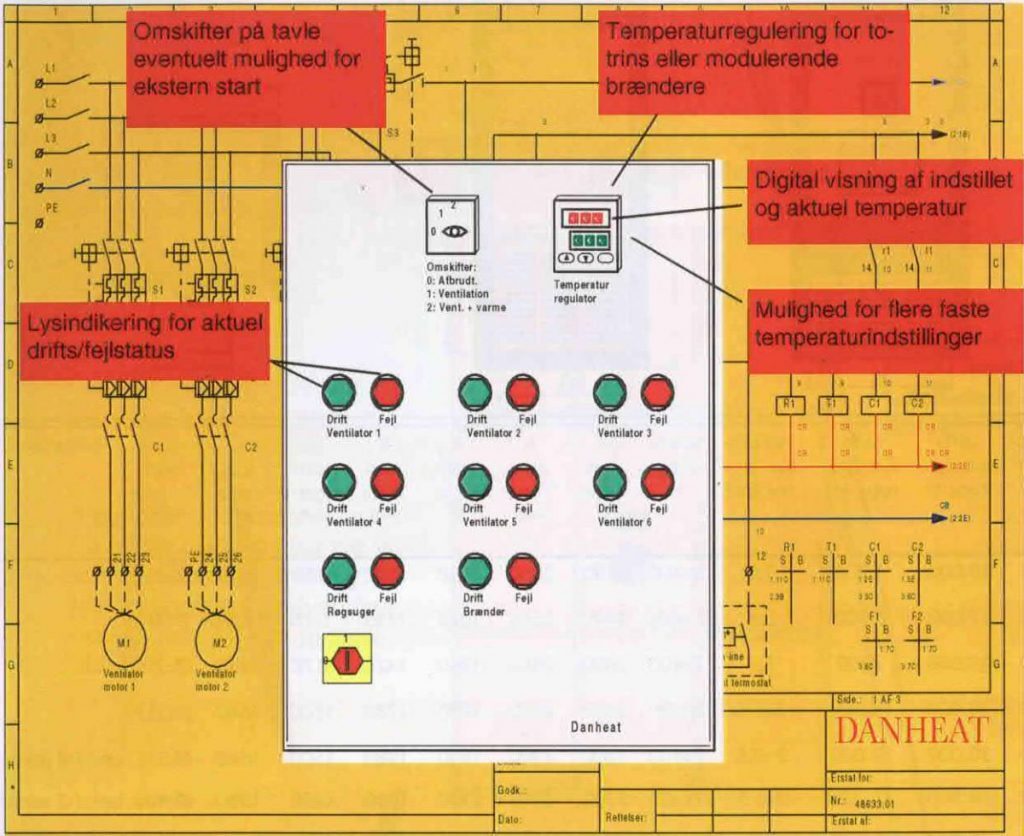

DANHEAT control panels

The control panel must first of all make sure, that the process air is supplied to the dryer with the right temperature. But also other functions are important to secure the heaters function and time of living.

- When the heaters starts up cold, the heat supply must be limited until the operating temperature has been reached. This is to prevent any unnecessary load on the steel plates so that no shock cracks appears.

- The fans are connected phased, so that the start circuit does not overload the electrical circuit.

- The fans must not be able to stop without after-cooling the heat supply after the oil/gas burner is disconnected.

- The burner must not be able to connect if a failure appears on the fan.

- The control panel must show the actual operating or disfault status.

- The control panel must be able to start and stop externly.

- The control panel must show the actual operating or disfault status externly.

Of course Danheat control panels fulfill all these demands. Besides this the control panels can be mounted with components, so that is fulfills the demands for just your heating need.