Information about wood drying

How to get optimal wood drying

Drying wood has until now been associated with a very high energy consumption. In cooperation with Silkeborg Pallefabrik A/S, DANHEAT A/S has developed a system whereby the drying process can be optimized and the energy consumption is reduced significantly.

Drying of wood has hitherto been associated with a very high energy consumption, but by means of a recycling principle in the drying cabinet, where fresh air is only supplied during periods when the relative humidity is so high that the air cannot “carry” more water.

In a conventional drying plant, constantly heated fresh air is applied, which is immediately sucked out, this is very energy-intensive, as the air in this system is not steam-fired with major energy losses. At the recirculation system, not only is the heating energy reduced, but it also saves on electricity consumption. To a plant that can dry approx. 600 EUR pallets, the installed electric load is only 25 kW.

In other words, it is common sense to invest in a plant, and our specialists are advised to provide advice.

Electrical control

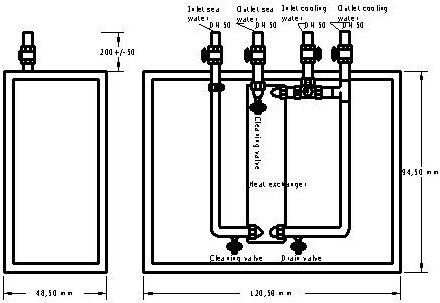

When the control is switched on, the temperature sensor registers the discharge temperature from the exchanger.

If the temperature is higher than the temperature setpoint set on the temperature controller, signal is sent to the 3/2 way control valve to increase the cooling water flow.

If the discharge temperature drops, the control valve will correspondingly reduce the flow of cooling water.

If there are deviations of more than 2 gr C at the current outlet temperature and the temperature set.

Accessories

Alternatively, in addition to the components described above, the switch can be fitted with:

Temperature regulator with alarm function: The sensors detect the temperature of return water and replacement water, if an error occurs between the two temperatures, an alarm is given.

Connection pressure switch for differential pressure’s pressure switch, as well as for differential pressure switches that emit alarm, if deposits begin to stop the heat exchanger.